Taconic PCB refers to printed circuit boards made using high-performance substrates produced by Taconic. Taconic is renowned for its substrates suited for high-frequency and microwave applications, known for low dielectric constant, low loss, high thermal stability, and excellent mechanical properties. Common Taconic substrates include TLY, RF-35, and CER-10.

Taconic PCBs are widely used in Communications,including mobile, satellite, and microwave communication equipment, radar systems,wireless modules for cellular and satellite base stations,high-performance antennas and antenna arrays,automotive Electronicssuch as in-vehicle radar and wireless charging systems,Medical Equipment: Especially in devices involving RF and microwave technologies.

XCE customers frequently use Taconic substrates like TLY-5, RF-35, and CER-10 for high-frequency PCBs due to their outstanding electrical performance and mechanical stability.

Manufacturing Challenges of Taconic PCB

Material Properties: The high thermal stability and low thermal expansion of Taconic substrates require precise control in the manufacturing process.

Precision Requirements: High-frequency circuits demand high precision, including accurate line width and consistent spacing.

Lamination Process: Special conditions are needed for laminating and stacking Taconic materials to prevent deformation and ensure proper bonding.

Processing Challenges: The physical properties of the materials can complicate drilling and cutting processes.

XCE’s Advantages in Manufacturing Taconic High-Frequency PCBs

1.Advanced Manufacturing Equipment: Equipped with specialized equipment for high-frequency PCB production, ensuring precise control over various parameters.

Our team of experienced engineers and technicians well-versed in the properties and processing requirements of Taconic materials. A stringent quality control system ensures that each PCB meets the required electrical performance and mechanical stability.

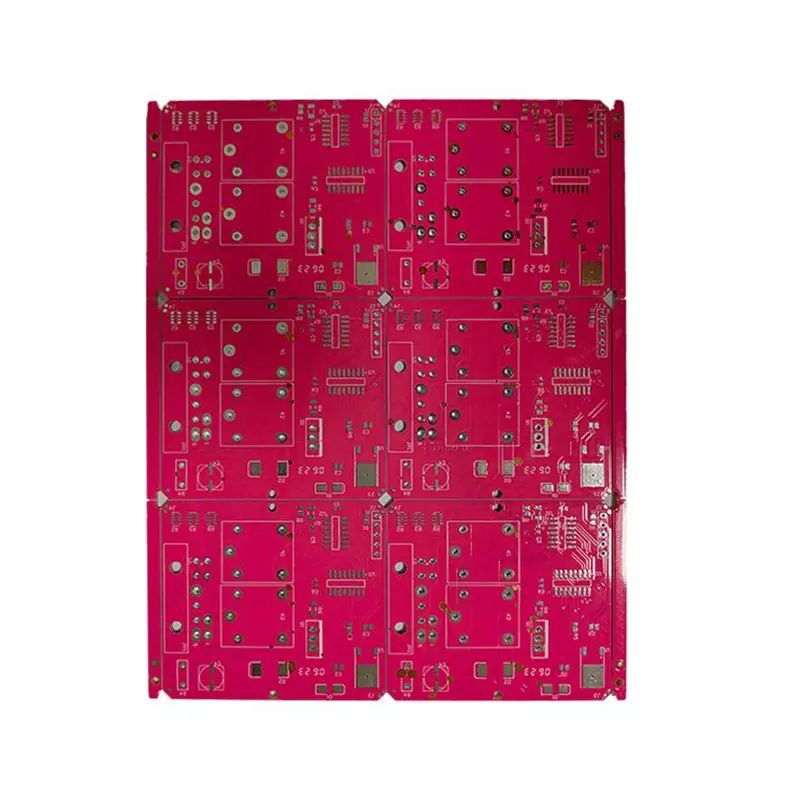

-

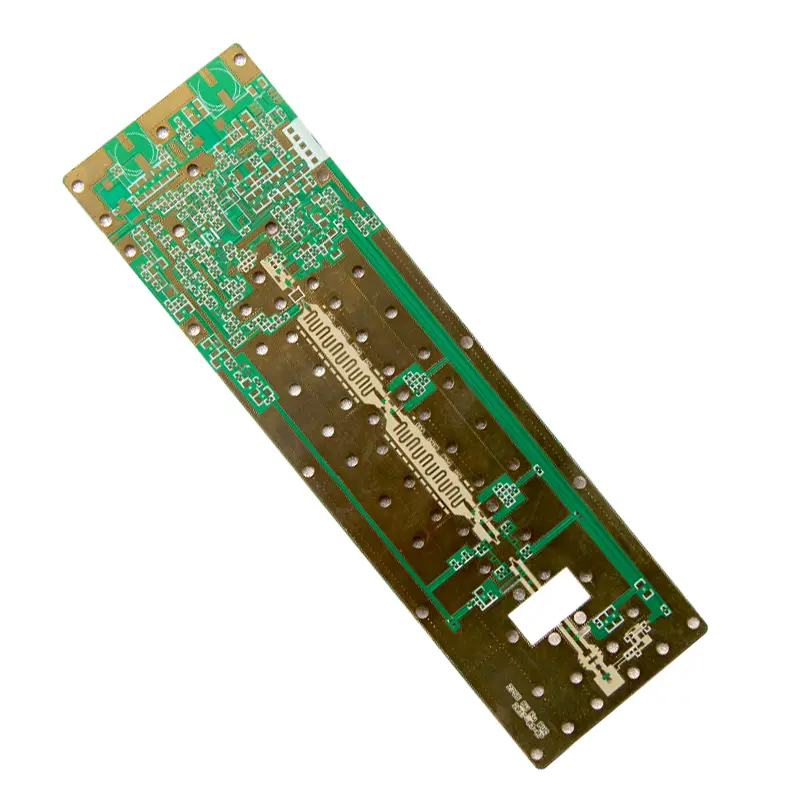

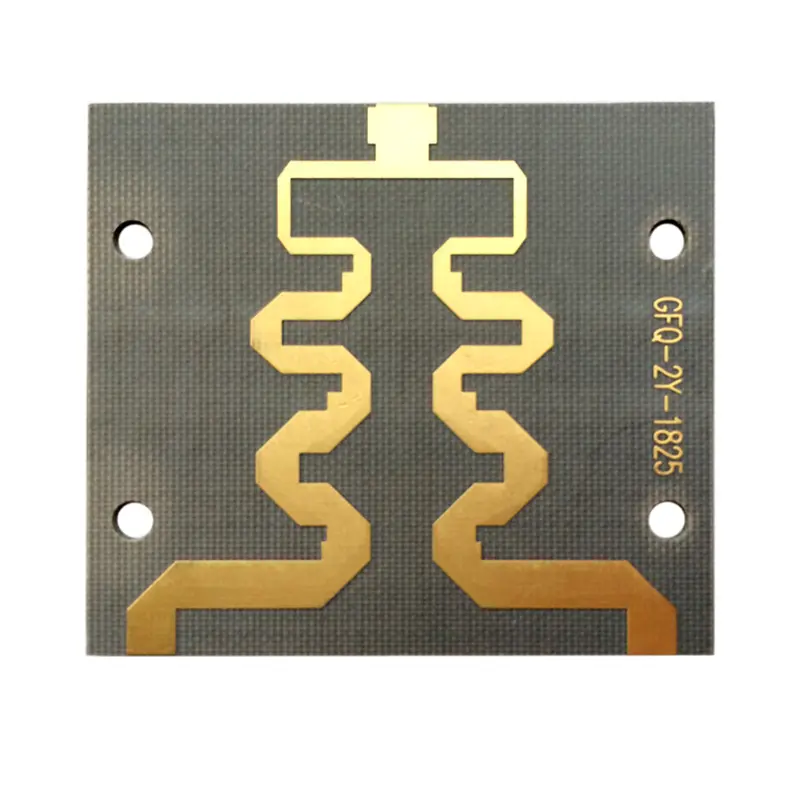

Taconic TLY-5A for power amplifiers

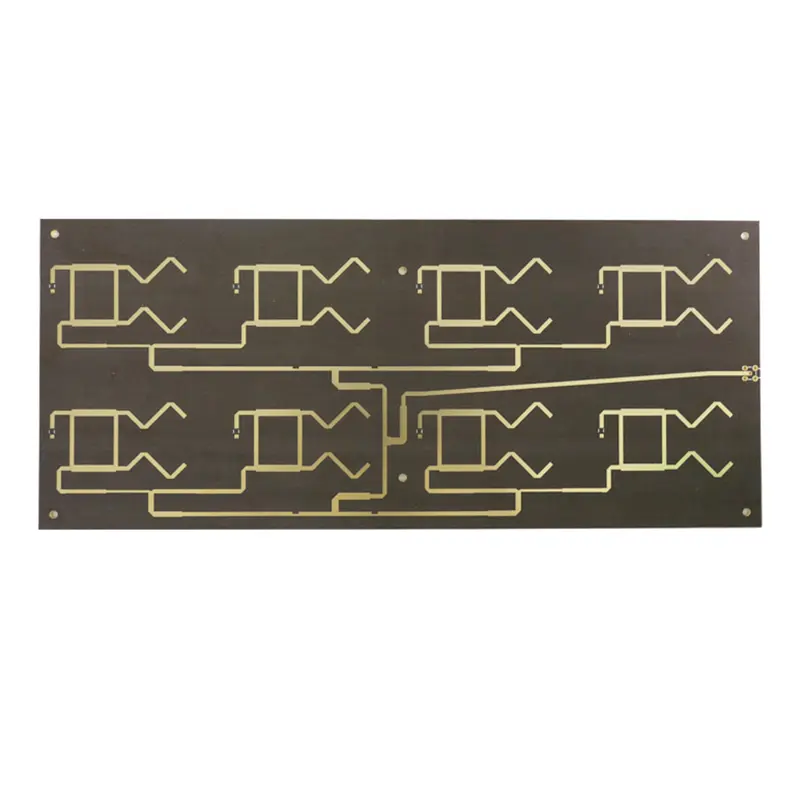

-

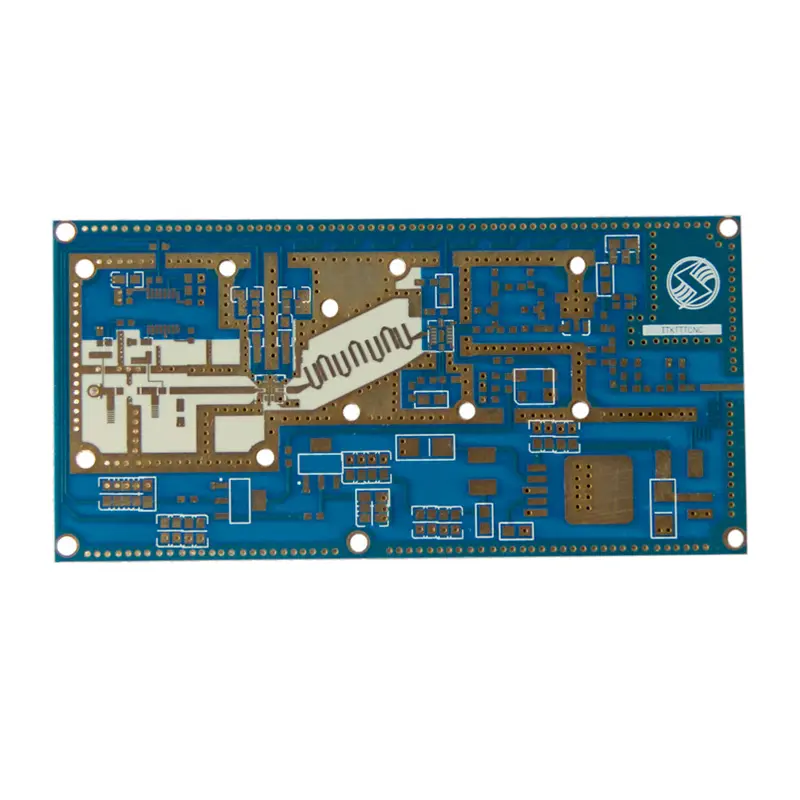

Taconic TP-2 high-frequency RF Microwave PCB

-

Taconic TP-2 Microwave Circuit Board for Wireless Modules

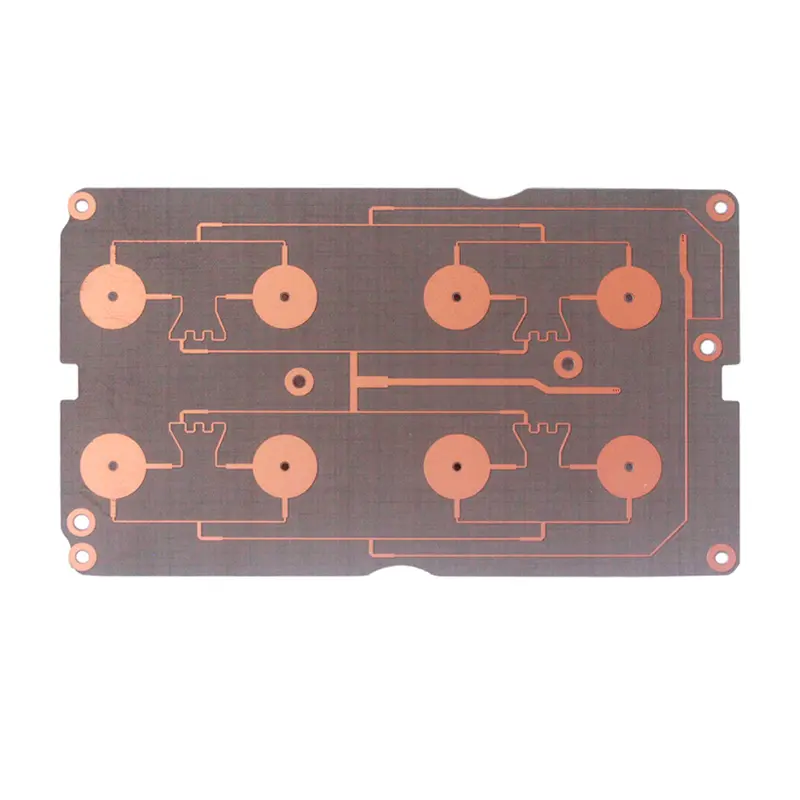

-

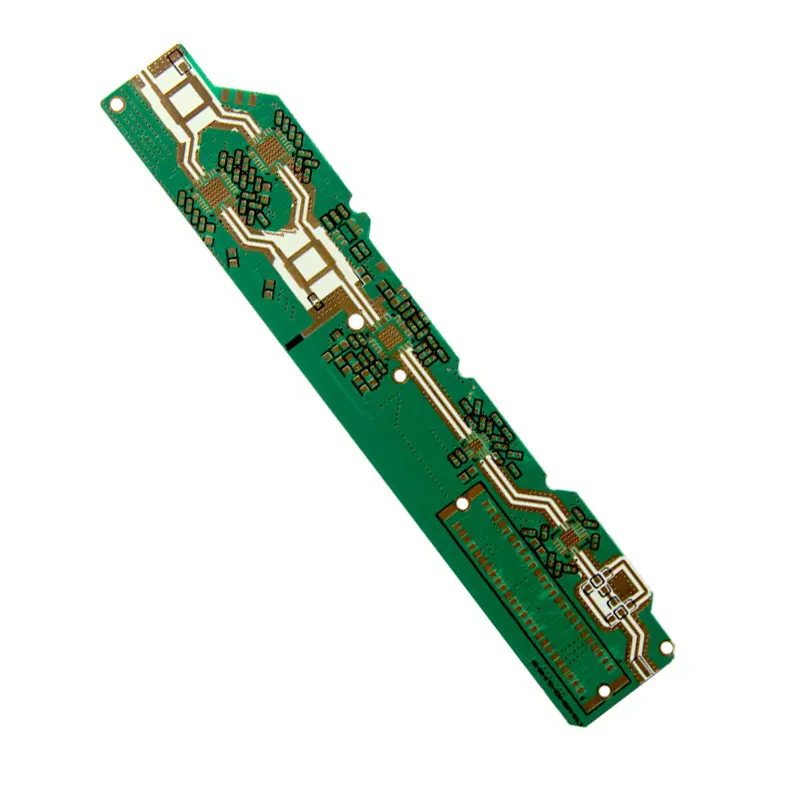

Taconic TP-2 RF PCB for Signal Couplers

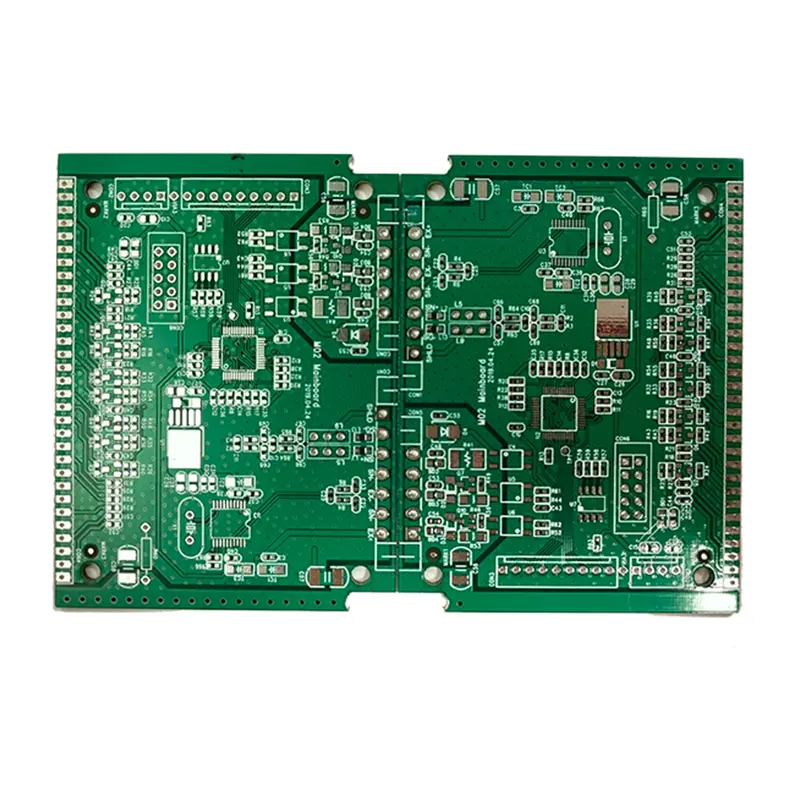

-

Taconic RF-35 microwave circuits board

-

Taconic RF-35 RF PCB

-

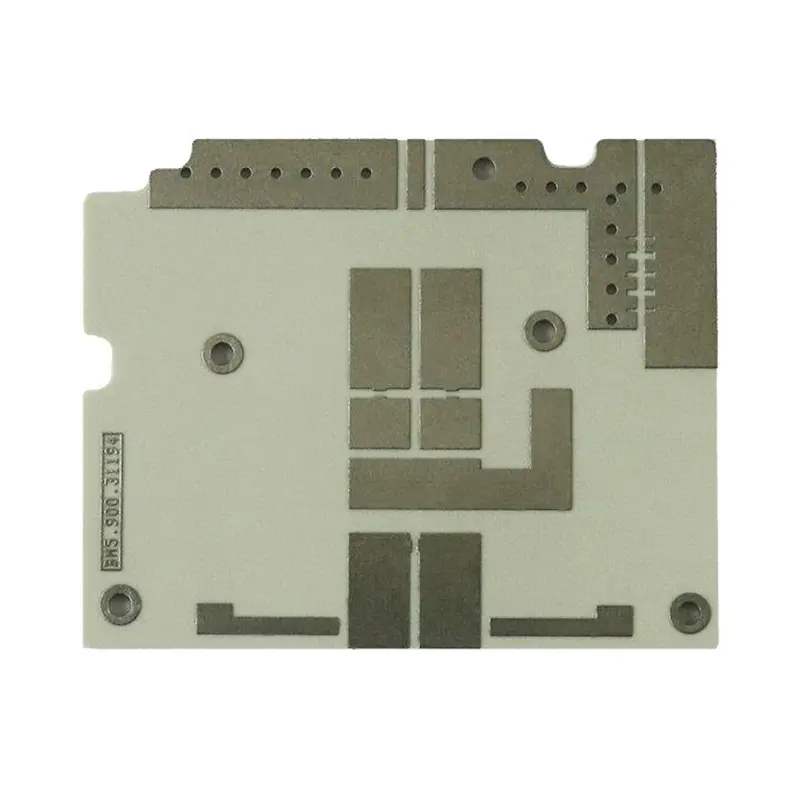

Taconic TLC Microwave PCB

-

Taconic TLT0 PCB in High-Performance Designs

-

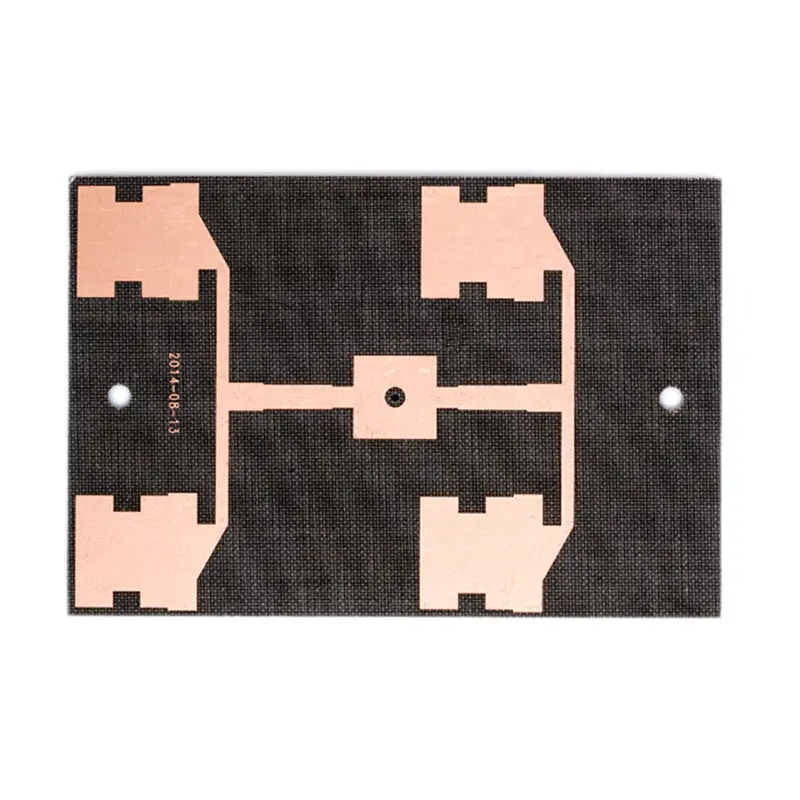

Taconic TLX PCB for Advanced RF Circuits

-

Taconic TLY-3 HF PCB

-

Taconic TLY-5 PCB in Satellite Communication

-

Taconic TLY-5 PCB in Wireless Communication