- +86 18038188537

- [email protected]

- Mon-Fri 9:00AM - 6:00PM CST, UTC+8

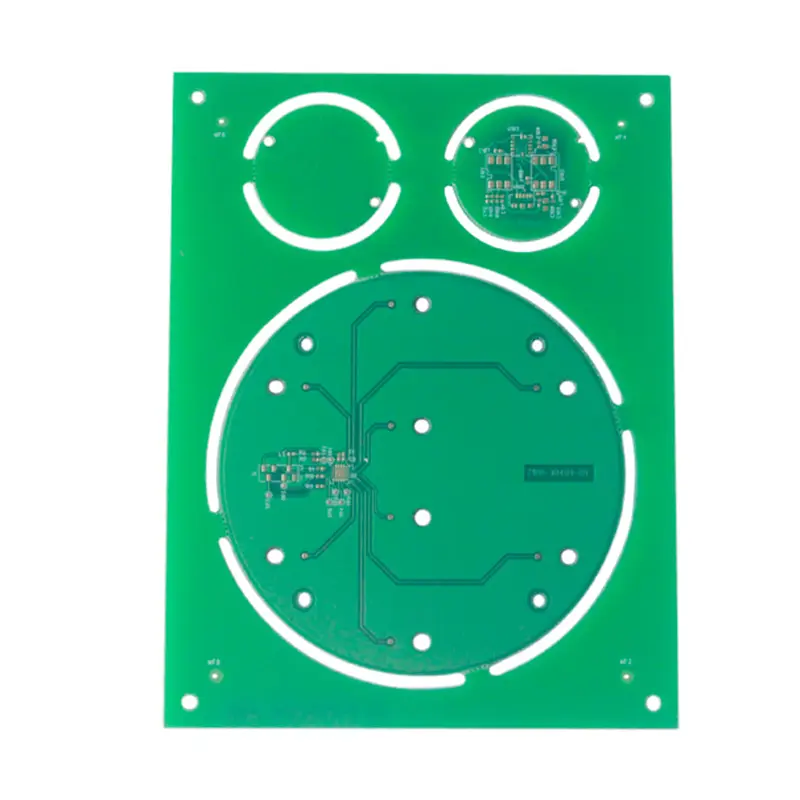

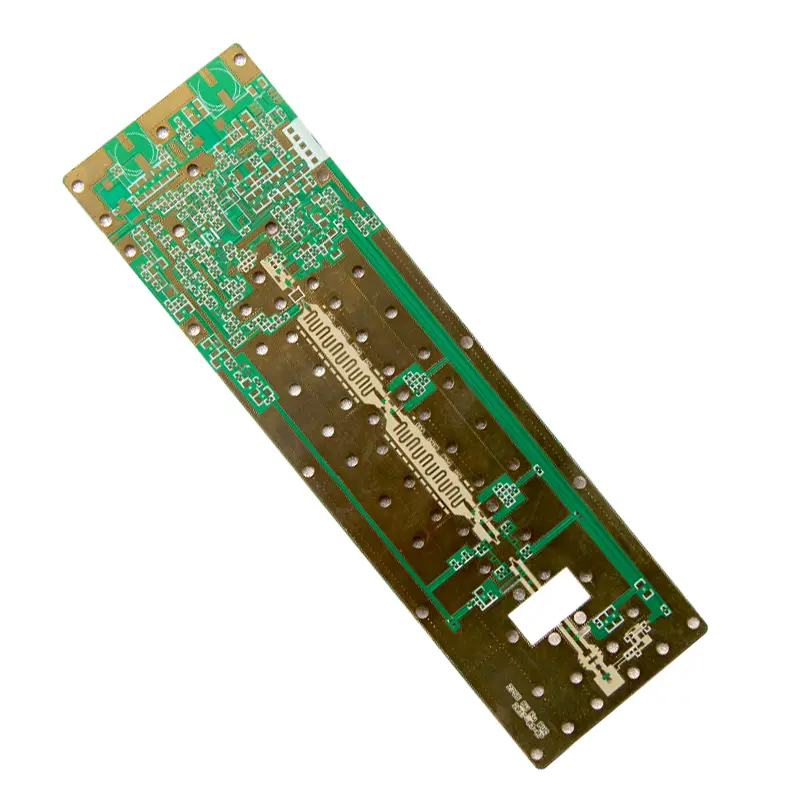

Rogers 4350B Microwave PCB is a high-performance solution designed for Multilayer PCB > 2-layers PCB applications. Key features include Number of layers: 2, Dissipation Factor (Df): 0.0037 at 10 GHz.

| Number of layers | 2 |

|---|---|

| Material | Rogers 4350B |

| Board Thickness | 1.524mm |

| Copper Thickness | 1 oz/ft² (35 µm) |

| Quality Standard | IPC6012 Class 3, IPC-A-600G Class3, or IPC-6015 |

| Dielectric Constant (Dk) | 3.48 at 10 GHz |

| Dissipation Factor (Df) | 0.0037 at 10 GHz |

| Product Type | RF Microwave |

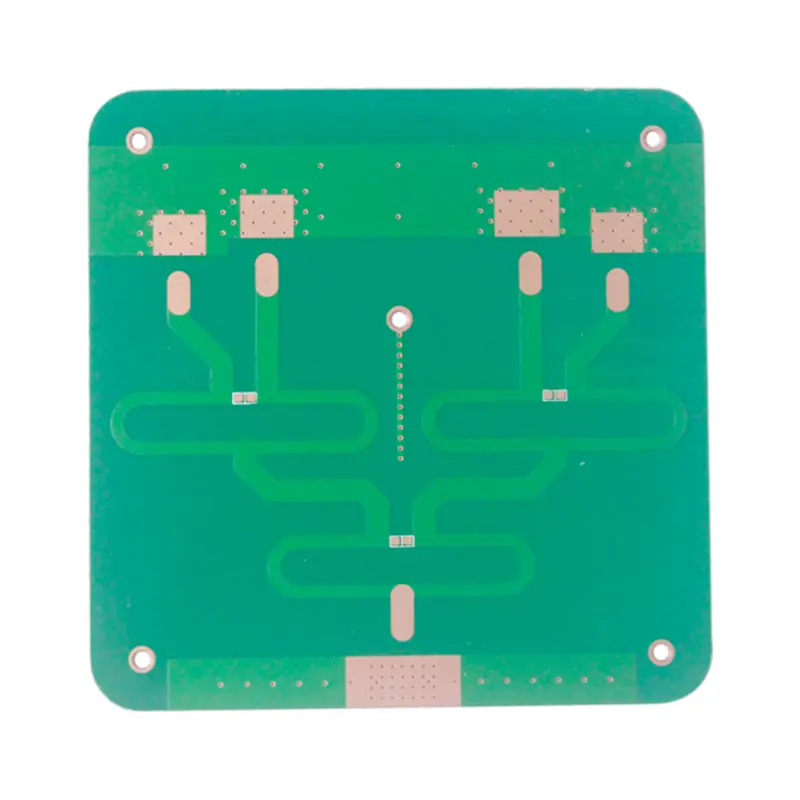

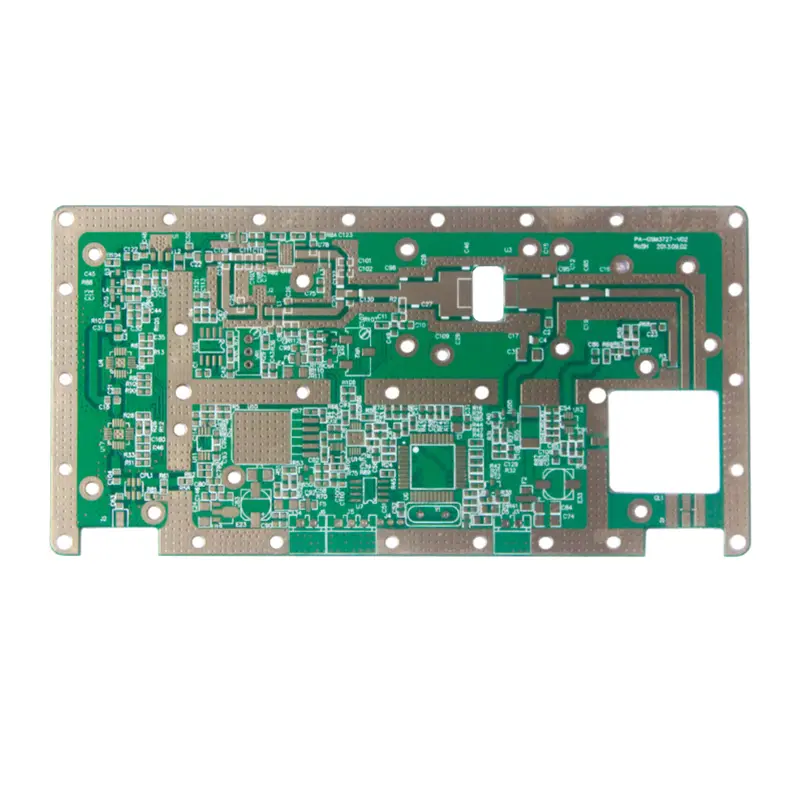

Rogers 4350B Microwave PCB is a premium choice in the field of Multilayer PCB > 2-layers PCB, High Frequency PCB, Multilayer PCB, PCB by Industries, RF Micorwave PCB, High Frequency PCB > Rogers PCB, PCB by Industries > Wireless PCB. It offers exceptional performance with Number of layers: 2, ensuring reliability and efficiency for critical applications. Designed for RF Microwave, this product excels in Dissipation Factor (Df): 0.0037 at 10 GHz. With advanced technology, it meets the demands of Multilayer PCB > 2-layers PCB, High Frequency PCB, Multilayer PCB, PCB by Industries, RF Micorwave PCB, High Frequency PCB > Rogers PCB, PCB by Industries > Wireless PCB, providing unparalleled quality. Perfect for professionals requiring high-frequency or specialized circuit performance, it remains an industry-leading solution in Product Type.

We offer a variety of high-frequency materials, including Rogers (e.g., RO4350B, RO5880), Taconic, and PTFE, depending on customer requirements.

Absolutely, we can provide detailed datasheets for review.

Our high-frequency PCBs can support frequencies up to 110 GHz, depending on the design and materials used.

We ensure precise impedance control through accurate stackup design, detailed impedance simulations, and advanced manufacturing processes.

Yes, we can combine materials like FR4 and high-frequency laminates for hybrid PCBs.

Restrictions mainly involve minimum trace width/spacing and material selection, depending on your design requirements.

We enhance thermal performance by using high thermal conductivity materials (e.g., metal-based PCBs) and optimizing copper thickness.

Thermal conductivity ranges from 0.2 W/m·K to 1.0 W/m·K, depending on the material.

ENIG/Gold Plating/Immersion Silver/Silver Plating/HASL/Gold finger/OSP/Nickel-palladium Gold/Resin plugging/Countersinking/ENIG+Hard Gold Plating/ImNi+ImTin/ENIG+OSP

ENIG is recommended due to its flat surface and excellent conductivity for high-frequency use.

We can produce high-frequency PCBs with layers ranging from 2 to 72.

Yes, we specialize in multilayer high-frequency PCBs and support hybrid stackup processes.

The thickness tolerance is ±0.05 mm, and the trace width tolerance is ±10%.

We perform impedance testing, RF performance testing, vacuum thermal testing, and more.

We achieve this by using high-quality materials, optimized manufacturing processes, and strict control of board thickness and other parameters.

Answer: Prototypes typically take 2–7 business days, while mass production takes 6–15 business days, depending on order volume and complexity.

High-frequency materials (e.g., Rogers) are more expensive, and higher layer counts increase complexity and cost.

We ensure reliability by using high-quality materials, rigorous testing, and optimized manufacturing processes.

Yes, our PCBs can endure temperatures up to 260°C and are suitable for harsh environments.

We use anti-static bags, vacuum packaging, and shockproof padding in the outer cartons for protection.

We provide air freight, express delivery, and sea shipping, depending on your needs, DHL is always prefered that ensure timely delivery through reliable logistics.